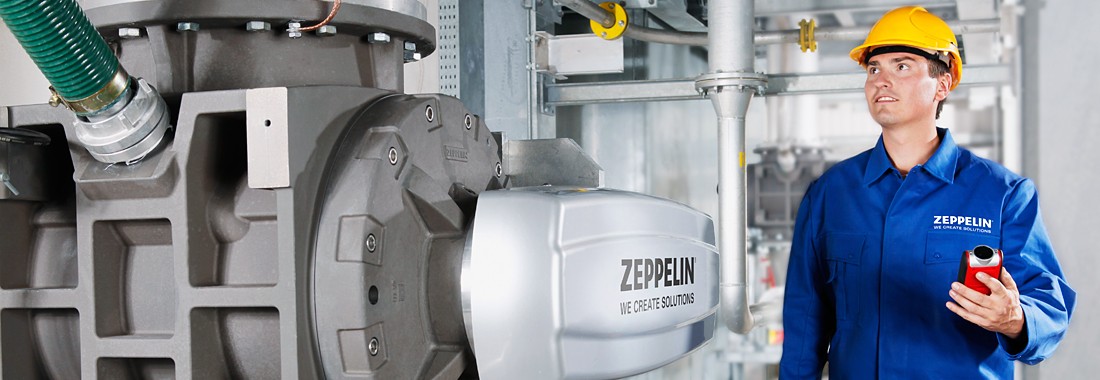

Discharge and dosage module KOKEISL

Reliable discharging and precise dosing becomes child‘s play with the mechanical discharge and dosing module ADM type KOKEISL. Diverse types of bulk materials can be filed from silos and containers to other containers in any amount with an extremely high degree of output rate accuracy. The KOKEISL technology is suitable for use in the food and plastics industry, the chemical industry as well as in the agricultural sector

Ultraflexible application

The technology has been part of Zeppelin’s range since 2012 and has been implemented in more than 300 new applications in all industries including food, plastics and the demanding field of pharmaceuticals.

The KOKEISL technology stands above all for uncomplicated usage when discharging bulk material from silos, containers and other vessels. Thanks to the system’s high flexibility, various bulk materials can be efficiently and accurately discharged from vessels in any amount desired. From a few grams to several tons of material, discharge is realized accurately according to the scale resolution.

The technology is also flexible when it comes to the type of process. Not only can it be used for local applications such as dosing on a single machine, but it can also be integrated into highly automated bagging machines, complex multi-component weighing systems, or even complete container systems. The KOKEISL technology provides interesting solutions for feeding from silos and vessels into pneumatic conveying systems, bagging machines and dosing systems.

Thanks to its electropolished surfaces and seals conform to FDA regulations, the KOKEISL is also suitable for the pharmaceutical industry. Furthermore, the KOKEISL consists of a few components only and is therefore very easy to clean. In principle, wash in place (WIP) is possible. The dosing slide can be easily disassembled and the components can be cleaned and dried individually according to the level of cleanliness required. The cleaning process can be customized.

When other discharge and dosing systems have failed, the KOKEISL is the system of choice when it comes to handling bulk material with poor flow characteristics. The specially-designed KOKEISL fluidizator rotates near the inner cone wall to prevent the formation of bridges while lifting and loosening the bulk materials before they are extremely gently discharged by gravity. A dosing slide below the fluidizator serves as valve as well as regulating device for the product flow (dosing). The discharge volumes can be infinitely regulated according to the dosing process.

There are numerous advantages for using the KOKEISL rather than a conveying screw: the components do not require an additional end cap to prevent product loss at the end of the dosing process. A vibratory bottom is also generally not required. There is considerably less space required for the same performance, as well as an overall enormous savings potential due to the omission of costs for assembly and control technology.

The discharge and dosing module ADM type KOKEISL is available in three sizes with a maximum outlet aperture diameter of 90 mm, 150 mm and 200 mm. With the input of the customer, the appropriate size is determined according to the tasks to perform.

The system is suitable, for example, in the food, plastics and rubber industries where highly flexible and precise mixing of raw materials is required as well as for dosing metal powder – directly from the container or infinitely regulated discharge from silos and vessels. The KOKEISL technology is also suitable for various industries such as pharmaceuticals, food, plastics, chemicals and agriculture for a wide range of products like spices, vitamin powder, lactose, sorbitol, starch, talcum powder, sulfur, calcium carbonate, powder pigment, and chocolate chips.